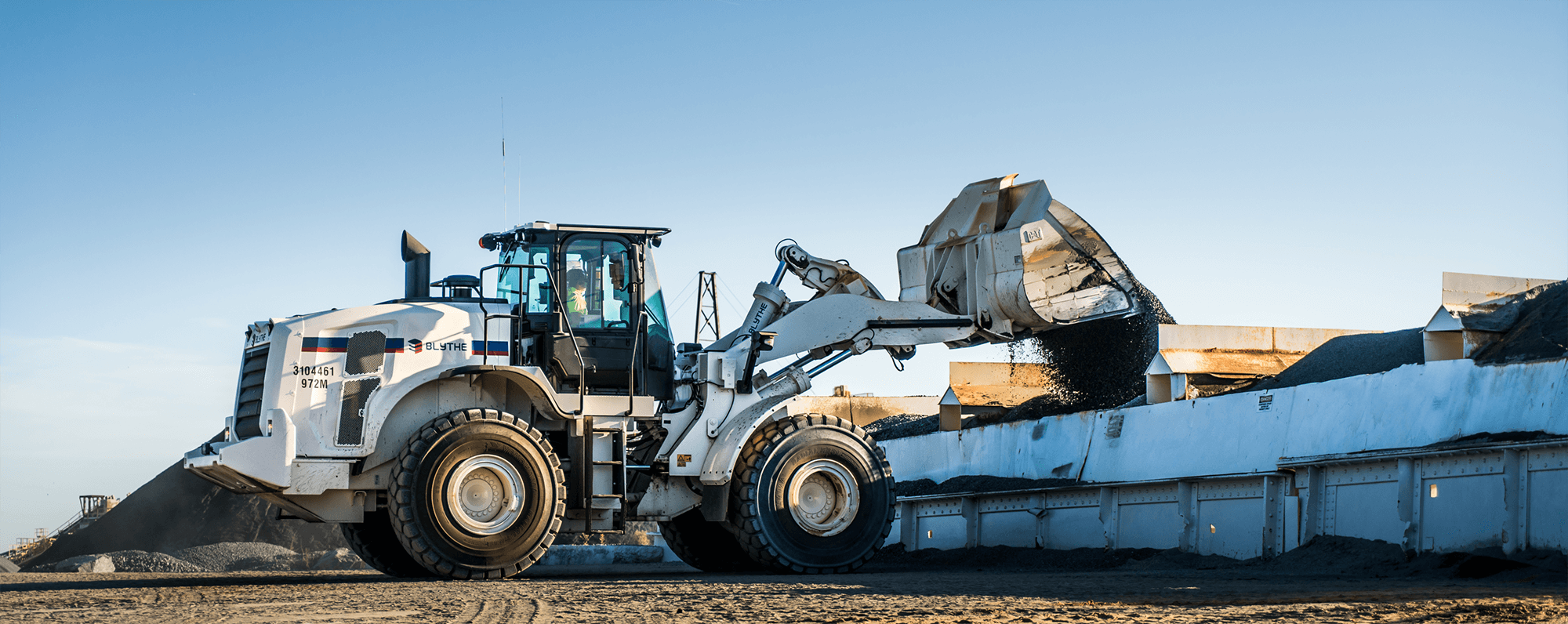

Blythe Construction is partnering with its European parent company, Eurovia-VINCI, to create a global operations system for use in 15 countries throughout the world. The project, which has been in the works for years, will finally begin this spring in Paris, France. Employees from all 15 countries and every major division of company operations will […]

Read More